Overcoming SAP Implementation Constraints in the Manufacturing Industry

Table of contents

- Major Business Benefits of SAP for Manufacturing Industry

- SAP Implementation Constraints in the Manufacturing Industry

When thinking about technology innovation in the enterprise, supply chain and manufacturing might not be the first areas that come to mind. However, a closer examination of history shows that these sectors have consistently been at the forefront of innovation, always looking for new solutions to enhance efficiency and productivity. From the introduction of assembly lines to the adoption of lean manufacturing principles, the manufacturing industry has continually evolved to meet the demands of the market. Today, this tradition of innovation continues with the implementation of advanced ERP systems like SAP implementation.

However, despite the clear benefits, SAP implementation in the manufacturing industry can be fraught with challenges. In this blog, we will explore these common constraints and how ITP, as a leading digital transformation partner, helps mid-sized and large manufacturing companies overcome them.

Learn how ITP expertise in SAP/Microsoft solutions to address current manufacturing challenges.

Like other core industry sectors, automation and digitalization are the future of manufacturing. Both these evolving trends are useful in meeting various complex challenges. Some of these challenges are- quicker turnaround, ever-changing demands, and supply chain constraints. Here, the SAP implementation solution lends a helping hand. It makes the entire process more resilient and ready for the future.

SAP digital manufacturing solutions can optimize core processes. Here, a built-in tool SAP manufacturing intelligence, integration, and analytics can remain helpful.

As a result, manufacturing companies can get higher productivity and efficiency. But, you need to consult a reliable global SAP partner.

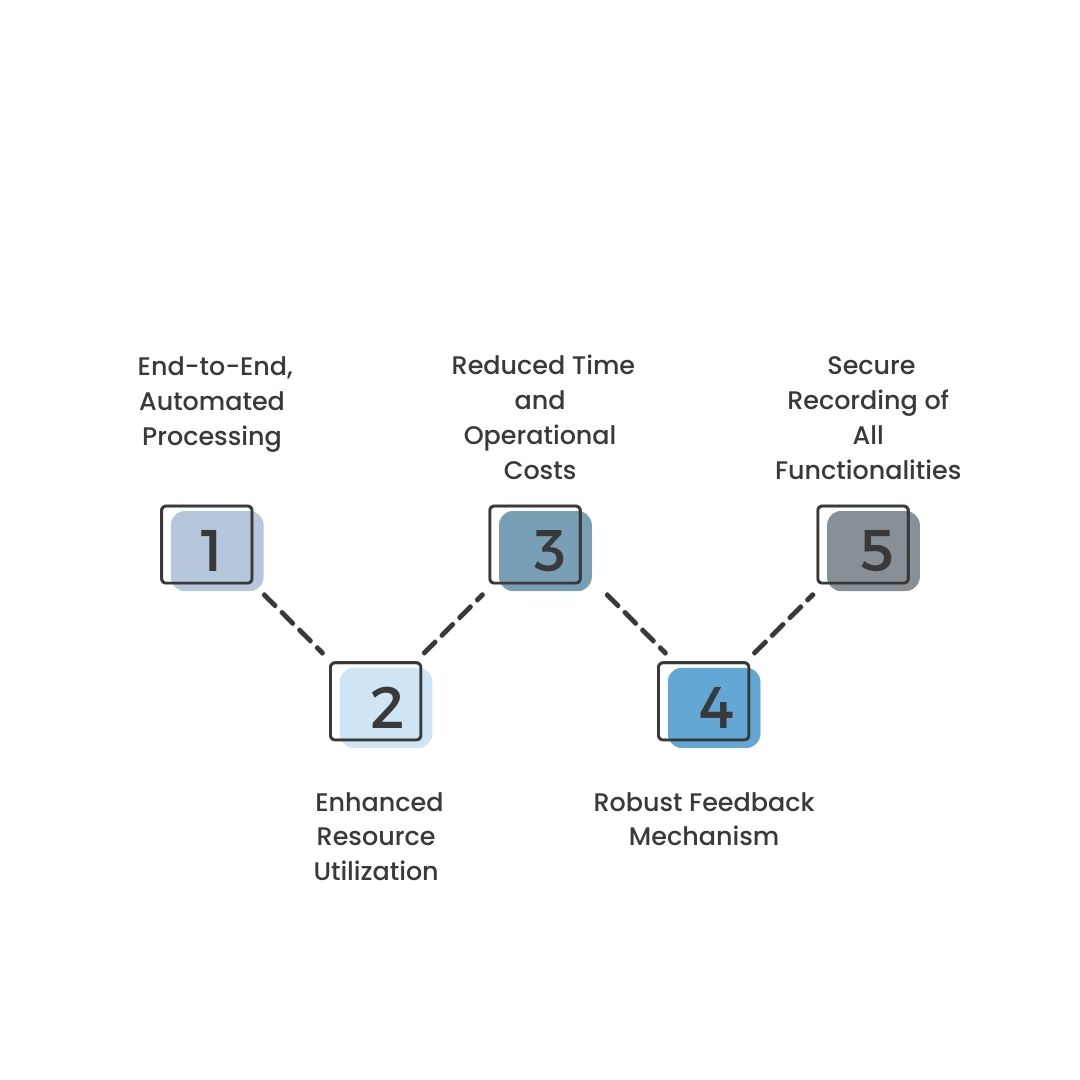

Major Business Benefits of SAP for Manufacturing Industry

Implementing SAP ERP in the manufacturing sector can lead to significant improvements in productivity and efficiency. Here are some of the key benefits:

1. End-to-End, Automated Processing

SAP ERP streamlines operations through automation, ensuring seamless integration across all departments, from production planning to inventory management and sales. This reduces manual intervention, minimizes errors, and accelerates workflows.

2. Enhanced Resource Utilization

By providing comprehensive insights into resource availability and utilization, SAP ERP helps manufacturers optimize the use of materials, labor, and equipment. This leads to more efficient production schedules and better resource allocation.

3. Reduced Time and Operational Costs

Automating routine tasks and improving process efficiency reduces operational costs and shortens production cycles. SAP ERP helps identify and eliminate bottlenecks, leading to faster turnaround times and cost savings.

4. Robust Feedback Mechanism

SAP ERP facilitates continuous improvement through its robust feedback mechanism. Real-time data and analytics provide actionable insights, enabling manufacturers to make informed decisions and implement necessary adjustments promptly.

5. Secure Recording of All Functionalities

With SAP ERP, all operational data is recorded securely, ensuring compliance with industry regulations and safeguarding sensitive information. This secure data management enhances transparency and traceability across the manufacturing process.

Implementing SAP ERP in the manufacturing industry offers these and numerous other benefits, ultimately driving high productivity and efficiency.

Similar articles