Manufacturing Digital Transformation: Top Technologies in 2022

Table of contents

- What is digital transformation?

- Why is digital transformation in manufacturing important

- Checklist for digitization of manufacturing

- Top digital transformation technologie

- Conclusion

- FAQ

Today, most industries use all the leading modern technologies associated with digital transformation. Thanks to them, production productivity is growing, costs are decreasing, and profits are growing. Read about how technology is helping to digitalize the industry, and how our expertise can help you with that. Did you know that digital transformation in manufacturing is already changing the world?

What is digital transformation?

Digital transformation is the introduction of modern technologies into the enterprise’s business processes. This approach involves not only the installation of contemporary hardware or software but also fundamental changes in approaches to management, corporate culture, and external communications. As a result, the productivity of each employee and the level of customer satisfaction increase. The company gains a reputation as a progressive and modern organization.

The digitalization of manufacturing processes is relevant not only at the level of individual enterprises: entire industries choose this development path as the only way to meet the rapidly changing conditions. Thanks to this, the digital transformation of industry, retail, public sector, and other areas is already changing the lives of every person and every company.

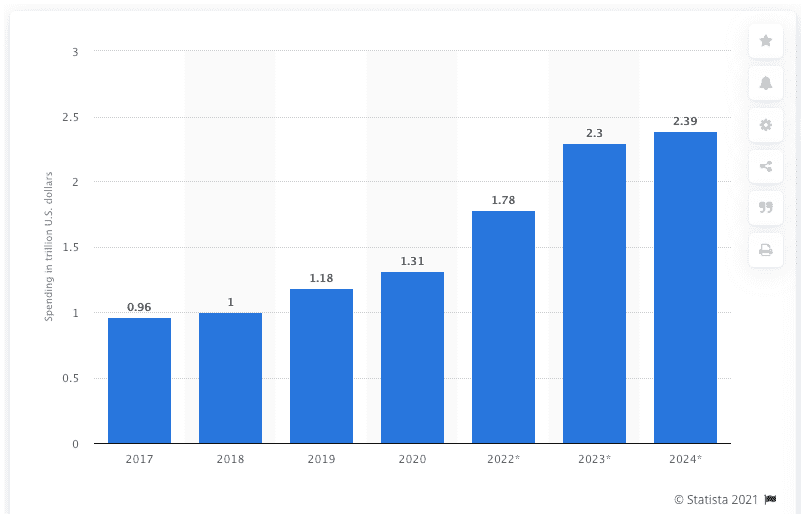

Spending on digital transformation technologies and services worldwide from 2017 to 2024

Why is digital transformation in manufacturing important

Digital transformation in manufacturin is, without exaggeration, the main direction of the industry’s technological development. Modern industrial production uses digital and computer technologies in all aspects of its work. From direct control and process control to business planning and workflow, almost all processes are currently carried out using digital data and digital infrastructure.

Moreover, digital transformation in manufacturing allows an organization to respond to constant changes in the market situation. Such a difficult fundamental change requires a complete overhaul of the culture, operations, technologies, and principles of creating new business products and services. Once this process begins, an organization’s digital transformation will impact products and services, marketing and distribution channels, business processes, supply chains, and new market partners.

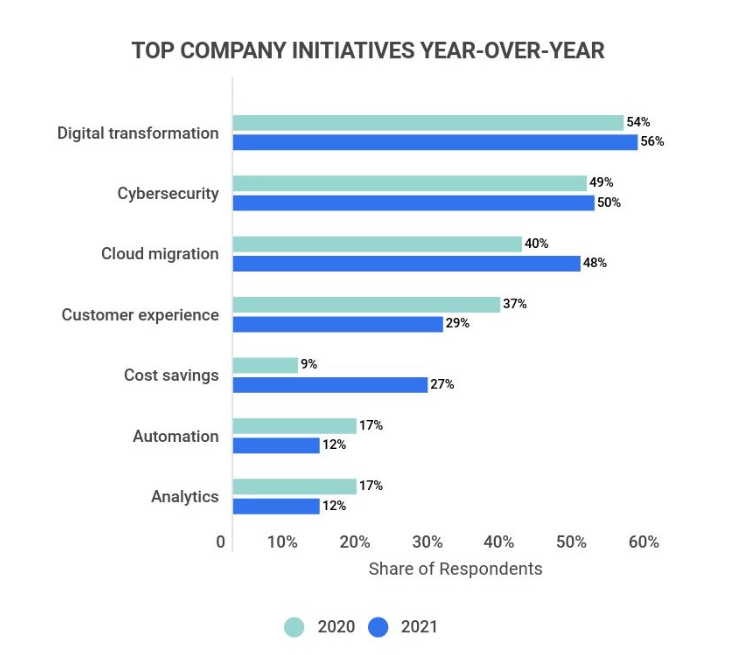

56% of companies are currently prioritizing digital transformation worldwide as of 2021

Checklist for digitization of manufacturing

First, you need to have a production map of the enterprise to identify bottlenecks and determine the highest priority nodes for optimization.

Then, finding a bottleneck associated with sales of products. Often, this can be a poorly controlled cost related to the lack of a flexible settlement system and a delay in delivery due to the lack of practical production planning tools.

Finally, ask key people in the enterprise: what problems they see, the causes of these problems, and how to fix them. Next comes the implementation phase.

Top digital transformation technologie

Internet of Things

Devices and machines on the Internet of Things can send and receive digital data. Equipment logs and maintenance reports are analyzed to optimize performance and improve efficiency. AI-powered business systems constantly analyze this information to identify patterns, trends, and correlations. The insights you gain help you perform predictive maintenance and create automated workflows, improving efficiency and productivity as machine learning applications learn from IoT data.

Robotics

Both robotics and RAP use automated processes to perform repetitive or pre-programmed tasks. Robotic devices are made up of moving mechanical parts designed to perform specific physical tasks. RAP processes are similarly programmed and automated, but they are software devices, not physical devices, and the tasks they perform are administrative.

AI and machine learning

Big data has evolved in parallel with artificial intelligence and machine learning. To process and use big data, the capabilities of AI and ML are indispensable. And for artificial intelligence and machine learning to produce accurate and meaningful results, they need datasets large enough for reliable training and analysis. The symbiosis of big data, artificial intelligence, and analytics is at the heart of business transformation and digitization of manufacturing. It opens up the possibility of predictive planning and flexible automation.

Companies in the aerospace, automotive, defense, consumer goods, medical and other industries are adopting digital manufacturing tools as they move towards Industry 4.0. 3D printing is a catalyst for productivity gains for a range of employees, from technologists to mechanics, and provides a company with the tools to shorten the supply chain, improve manufacturing efficiency, and accelerate time to market, saving hundreds of thousands of dollars and weeks of work.

With the development of 3D printing technologies, a wide area of their application in the manufacturing sector has opened up. Multifunctional desktop 3D printers and flexible polymers enable the production of highly accurate, functional 3D models that can replace final parts and withstand the rigors of the manufacturing floor.

Start a project with us!

Let's Do This!

Augmented and virtual reality

The has learned how to make the most of augmented and virtual reality technologies to reduce costs, streamline processes, improve security and improve the quality of corporate education.

VR/AR is a part of a company’s digital transformation in industrial manufacturing and immersive projects. Like any other IT implementation, it requires a well-thought-out implementation strategy, preliminary analysis and collection of information, and monitoring of the effectiveness of solutions.

The work of employees in industrial enterprises is almost always fraught with risks, interacting with complex or even dangerous equipment, repairing unforeseen breakdowns, and internal corporate communication. For industrial companies, specific practical skills of workers are critical – working with specific hazardous substances and equipment. And literature, corporate portals, or memos will not help here. Such skills develop in people only in practice and training with mentors. But the time spent on training personnel to work with equipment can cost enterprises tens of millions of dollars because these are paid hours for trainers and staff, possible breakdowns, and emergencies. VR/AR technologies reduce risks and costs, increase safety, and make learning more visual and understandable.

Cloud services

Cloud infrastructure is an essential component of successful digital transformation in smart manufacturing and the creation of IoT networks and connected business systems. With centralized, on-demand access to all systems, assets, and data, you can scale your infrastructure and adjust and automate workflows. It is a necessary foundation for rapidly changing business priorities and operating models.

Conclusion

Digital manufacturing in manufacturing is a way to achieve several goals at once, including the production of small batches of products with maximum efficiency, intelligent planning of maintenance and repair activities, and the systematic reduction of downtime. This is a concept that can be realized with our program, which involves the integration of hardware, software, and services.

FAQ

Digital transformation of business is a massive introduction of digital technologies into the business process. As a result, production efficiency is significantly increased, costs are reduced, and the manufactured product becomes “smart”.

Shortly, a project approach to business and the use of data-driven solutions, machine learning, and artificial intelligence, as well as modern methods of communication and continuous tracking of efficiency, will become mandatory attributes of any good company.

You will get a flexible and competitive company with more qualified employees and satisfied customers, which will positively affect the business’s financial performance.

Similar articles