Manufacturing Trends in 2024: AI Revolutionizes Warehouse Management

Table of contents

Ever wondered how warehouses manage to handle millions of products efficiently? Or maybe your company is facing challenges with warehouse management? In today’s discussion, we’ll uncover how AI can be the game-changer you’ve been looking for. Join us as we explore innovative solutions to streamline your operations and boost efficiency. Whether you’re dealing with inventory issues, logistical bottlenecks, or safety concerns, AI in warehouse management offers compelling answers.

One of the most significant manufacturing trends shaping this evolution is the adoption of AI-based solutions, particularly in warehouse management. In this blog, we explore how these technologies are revolutionizing operations, drawing insights from ITP’s case studies showcasing digital transformation from vision to reality.

Manufacturing Trends and AI: Applications and Benefits

As we move further into 2024, the manufacturing industry continues to evolve at a rapid pace, driven by technological advancements and the need for enhanced efficiency and safety. One of the most significant trends shaping this evolution is the adoption of AI-based solutions, particularly in warehouse management. In this blog, we explore how these technologies are revolutionizing operations, drawing insights from a case study featuring ITP’s cutting-edge AI-powered computer vision solutions.

Benefits of AI in Manufacturing

AI in manufacturing is not only transforming warehouse management but also revolutionizing various aspects of manufacturing.

In design and process improvement, AI in manufacturing, combined with virtual reality (VR) and augmented reality (AR), helps reduce design time and optimize assembly-line processes by improving the speed and precision of line workers. Predictive maintenance is another area where AI in manufacturing models can predict machinery failures, preventing downtime and extending the lifespan of equipment.

For quality inspection, AI systems in manufacturing analyze vast amounts of data from manufacturing processes to ensure quality control and detect defects. Additionally, AI in manufacturing can optimize energy consumption, reducing costs and the environmental impact of manufacturing operations.

Overcoming Challenges in AI Adoption

Despite the clear benefits, AI adoption in manufacturing faces challenges. Implementing AI requires specialized skills, which can be scarce and expensive, leading to a skills and knowledge gap. Manufacturers may also be resistant to change, being risk-averse and requiring exhaustive proof before investing in new technologies. Additionally, the high initial costs can be a significant barrier, especially for small and medium-sized enterprises (SMEs).

The Rise of AI in Warehouse Management

The Global Warehouse Automation Market is expected to reach USD 67.05 Billion by 2032, at a CAGR of 15.1% during the forecast period 2023 to 2032.

Read More: https://www.sphericalinsights.com/reports/warehouse-automation-market

AI-based solutions enhance safety and efficiency within the warehouse through advanced video stream monitoring. Key features include load zone monitoring, access control in restricted areas, compliance with storage standards, and detection of empty pallets to optimize space. Real-time notifications significantly improve security and the operational management of processes.

Artificial Intelligence (AI) has become a cornerstone of modern warehouse operations, providing tools that significantly improve safety, efficiency, and operational management. Companies like ITP are at the forefront of this transformation, leveraging AI to tackle various challenges faced by warehouses. Here, we delve into the specific applications and benefits of AI in warehouse management.

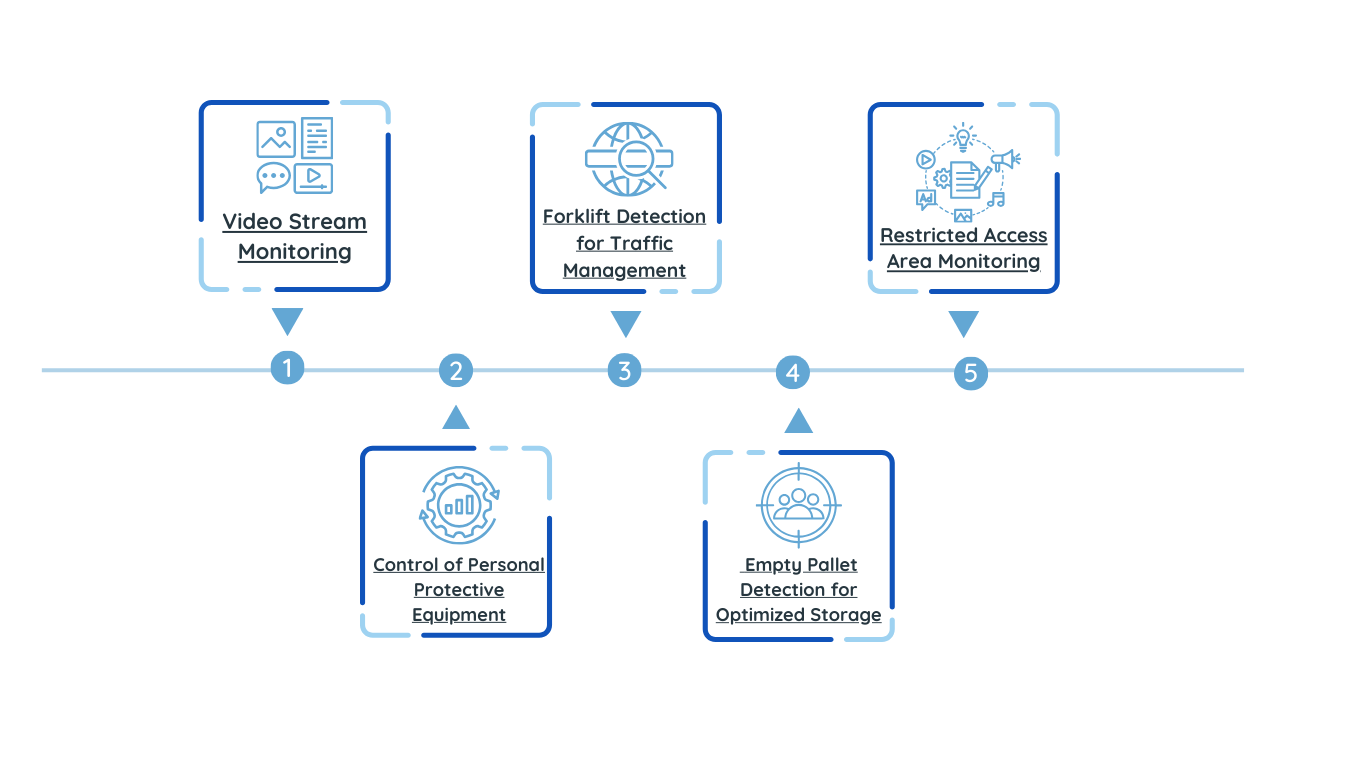

1. Advanced Video Stream Monitoring for Enhanced Safety and Efficiency

Objective: Improve overall warehouse safety and operational efficiency through real-time video stream analysis.

Solution: ITP’s AI-powered video stream monitoring system offers several key features:

- Load Zone Monitoring: Ensures safe loading and unloading processes by continuously monitoring designated load zones.

- Access Control: Manages and restricts access to sensitive areas, ensuring only authorized personnel can enter.

- Compliance with Storage Standards: Monitors adherence to storage guidelines, preventing overloading and unsafe stacking practices.

- Empty Pallet Detection: Identifies empty pallets promptly, optimizing space and inventory management.

Impact: The implementation of real-time notifications has significantly enhanced warehouse security and operational management, reducing the risk of accidents and improving process efficiency.

2. Forklift Detection for Traffic Management

Objective: Enhance forklift safety and traffic management within the warehouse.

Solution: Real-time forklift detection and monitoring system.

Key Features:

- Forklift Detection in Restricted Areas: Identifies forklifts entering restricted zones to prevent accidents and ensure compliance with safety protocols.

- Pedestrian Detection Near Forklift Zones: Monitors pedestrian movement around forklift areas, sending alerts to prevent collisions and injuries.

Impact: By integrating real-time monitoring, ITP has successfully reduced the risk of accidents involving forklifts, ensuring a safer working environment for all warehouse personnel.

3. Restricted Access Area Monitoring

Objective: Ensure security and compliance in high-risk warehouse zones.

Solution: AI-driven access control and monitoring system.

Key Features:

- Tracking Restricted Access Zones: Continuously monitors and tracks entry into restricted areas.

- Perimeter Access Control: Manages and controls access to the warehouse perimeter to prevent unauthorized entry.

- Compliance Enforcement: Ensures all actions within high-risk areas comply with safety and operational standards.

Impact: Enhanced security measures have significantly reduced unauthorized access and improved compliance, contributing to a safer and more secure warehouse environment.

4. Control of Personal Protective Equipment (PPE)

Objective: Ensure compliance with safety standards through effective monitoring of PPE usage.

Solution: AI-based PPE compliance monitoring system.

Key Features:

- Real-time Monitoring: Tracks the use of protective gear such as helmets, vests, and gloves.

- Notifications: Sends immediate alerts if PPE standards are not met, ensuring corrective actions are taken promptly.

Impact: The real-time monitoring and alert system have greatly improved PPE compliance, reducing the incidence of workplace injuries and ensuring a safer environment for warehouse workers.

5. Empty Pallet Detection for Optimized Storage

Objective: Improve storage and inventory management through efficient pallet usage.

Solution: AI-enabled empty pallet detection system.

Key Features:

- Camera-based Detection: Quickly identifies empty pallets, facilitating their efficient reuse.

- Space Optimization: Enhances storage space utilization by ensuring empty pallets are promptly relocated.

Impact: The system has improved warehouse productivity and safety by optimizing storage and inventory management, leading to better space utilization and reduced clutter.

Start a project with us!

Let's Do This!

As demonstrated in ITP’s case study, AI-based computer vision solutions are transforming warehouse operations, providing unprecedented levels of safety, efficiency, and operational excellence. In 2024, the manufacturing industry will continue to embrace these technologies, driving innovation and competitiveness. By adopting advanced AI tools, manufacturers can stay ahead of the curve, ensuring their operations are not only efficient but also safe and compliant with industry standards.

Partnering with leaders in digital transformation like ITP allows warehouses to leverage the full potential of AI, ensuring that every aspect of warehouse management is optimized. From traffic management and access control to PPE compliance and storage efficiency, AI is set to redefine the future of manufacturing.

Are you still curious about our solutions or wondering how we can assist you further? Schedule a free demo call today and experience firsthand how AI in warehouse management can streamline your warehouse processes, making them more efficient and productive!

Similar articles